The photo shows the Tesla Model 3 in which our lightweight parts are installed.

(*Courtesy of Tesla, Inc.)

The photo shows the Tesla Model 3 in which our lightweight parts are installed. (*Courtesy of Tesla, Inc.)

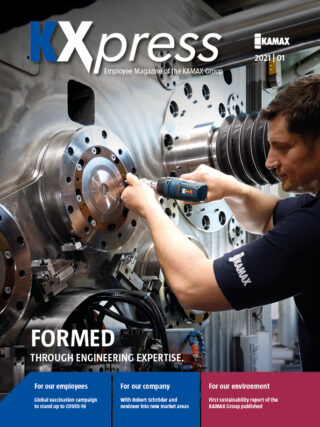

Since our company was founded in 1935 by Rudolf Kellermann, KAMAX has always excelled in one thing in particular: the art of engineering. Over the past decades, we have developed hundreds of products, filed numerous patents and set milestones in the field of cold forming and the manufacture of fasteners for the automotive industry. Below we take a look at the current work of our Technology departments in the USA, China and Germany.

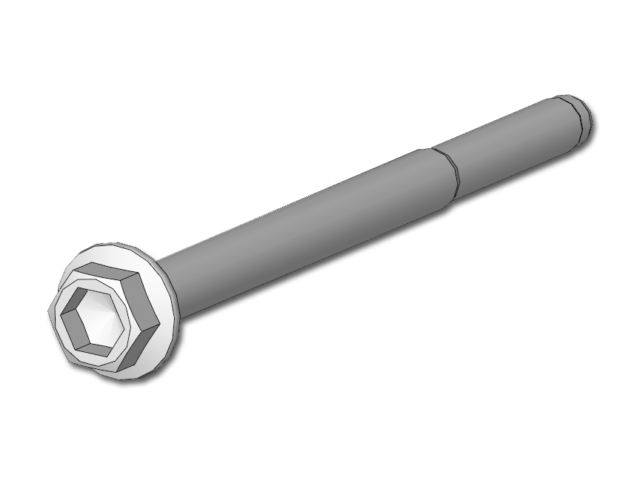

Lightweight design for Tesla

One of KAMAX’s fastest growing customers over the last couple of years has been Tesla. We are their primary fastener supplier in chassis and suspension applications for the Model 3 and Model Y. The engineering teams at Tesla have shown great interest in our innovation of lightweight designs. Both teams worked together to incorporate KAMAX’s design into Tesla’s standard. Any new part, if it’s a candidate for lightweight head, has been designed with this feature. One ongoing project is converting current parts we were awarded in 2017 for the Model 3 to lightweight design. Many of the same parts were carried over to the Model Y. Once fully implemented, this will save approximately 500 grams per vehicle. These parts will eventually be used globally and need to be produced by all KAMAX regions as Tesla China and Tesla Berlin continue to ramp up.

Lightweight fastener for Tesla

KAMAX Inc. in the US has recently been awarded new larger diameter lightweight head parts specific to the Model Y and refreshed version of the Model S. We have been manufacturing lightweight parts for a few years. These have primarily been M6 and M8 diameter. With the help from the Central Technology Department, these have been developed to run very efficiently in the cold header. The challenge has been the Tesla parts are M12 and M14. Tool life has not been optimal. Adjustments to current tool design are underway that should lead to even better results. All new designs and concepts introduce new challenges to overcome and the team is confident we will succeed.

US team responsible for Tesla lightweight design (f.l.t.r.): D. Burghdorf, D. Vogt, B. Price, M. Freeman, R. Darling

Innovation Hub tries new approaches

Strong changes are coming to our KAMAX product portfolio driven by the changing market demands. The fasteners typically used in today’s combustion engines will fade out in the future and new demands for solutions and products will arise, for example, from e-mobility or fuel cell technology. In June 2020 the Innovation Hub was established within KAMAX Technology. The role of this small department can be described in two main tasks: first, the creation and collection of ideas for new products and processes and second, the development promising ideas into next development phase resulting in a PoC (Proof of Concept).

The most important part of the process creating valuable ideas is to generate ideas at all. The more ideas we add to our process, the higher the chance that a valuable idea is among them. Therefore, we encourage all KAMAX employees to have an open mind and reach us whenever they have an idea and participate in this challenging journey. All new product ideas are collected into a database and its potential and feasibility will be studied. When one of them is considered “valuable”, the Innovation Hub will put together a team that will be in charge of taking this idea to the next level so that the concept is ready for further development in the TEC departments. In its short live Innovation Hub has until today registered more than 200 development ideas and worked out 32 feasibility studies and finished 2 proof of concepts studies. As an example the analysis and identification of future products, resulting from the emerging hydrogen-economy, may be mentioned. In this project not only products in the field of hydrogen driven vehicles (fuel cells) were analyzed, but also non-automotive applications in the area of the production or distribution of hydrogen or energy production by stationary fuel cells were evaluated.

Workshop at Innovation Hub

The development teams are formed specifically for each project, making sure that the team is cross-functional and interdisciplinary, combining all the competencies needed for the project. This means that every KAMAX employee can and should have the opportunity to be involved in the ideation and innovation process. By this, you have the chance to actively work on your idea, built functional prototypes and have fun testing it. The team should focus their workload on this project during the time of its development, which typically will last a couple of weeks or a few months.

You are interested in what ideas we are working on or have your own good idea? You want to learn about our work methodology? We are looking forward hearing from you: innovationhub@kamax.com

If you want to learn more about the methods of product and process development within our Technology department, you can find a detailed article here (note: only available in English).

CONTACT

Non-Bolt Street Chisels from Wujin

The Chinese team started in 2014 with only one employee and the job was mainly collecting the issues which occurred in production and send them to the US or Tools & Equipment (T&E) in Germany. We needed their support to change the tool design and get the problems solved.

“We are grateful that T&E and US colleagues offered us the help at the beginning. Occasionally, we received different ideas from different teams, so we really feel the importance of tool design standardization.”, says Junhua Ni, Vice Technology Manager at KAMAX in China. Operation Wujin started tool design localization in 2018 and also made tool design guide lines internally as we didn‘t have group standards. The focus was to optimize the forming process and change trimming to forming. With these efforts our cold heading tool costs went down from 46 RMB/Kpcs to 29.7 RMB/Kpcs* by the end of 2020 and cold heading scrap ratio went down to 3.02%.

New KX Non-Bolt Product: Street Chisel

Tool Cost (RMB/Kpcs)*

Since 2019, the team of Junhua Ni has added making TAPTITE parts, cam-bolts, spindles, double ended bolts, T bolts, KXtap bolts, one-piece cam bolts and chisels. The newest project is working on a M30 plug. The chisel is the first part developed in Wujin and it’s the first time they use open dies. Gaining experience with this is a major topic for the Chinese TEC team. Very helpful has been using the software SIMUFACT, which can simulate the forming process and offer KAMAX China the reference for the tool design especially for non-bolt products.

Further non-bolt products will bring in more challenges as well as opportunities not only for the Technology department but also for production and quality. “Start is always not that easy, but I am sure we will be able to improve the current production and extend the market where we are still blank with all the efforts from us!”, says Junhua Ni.

*RMB stands for the Chinese currency Renminbi/Yuan (1 Yuan = 0.15 Dollar = 0.13 Euro).

scrap rate (cold heading)

KXpress · 2021 | 01