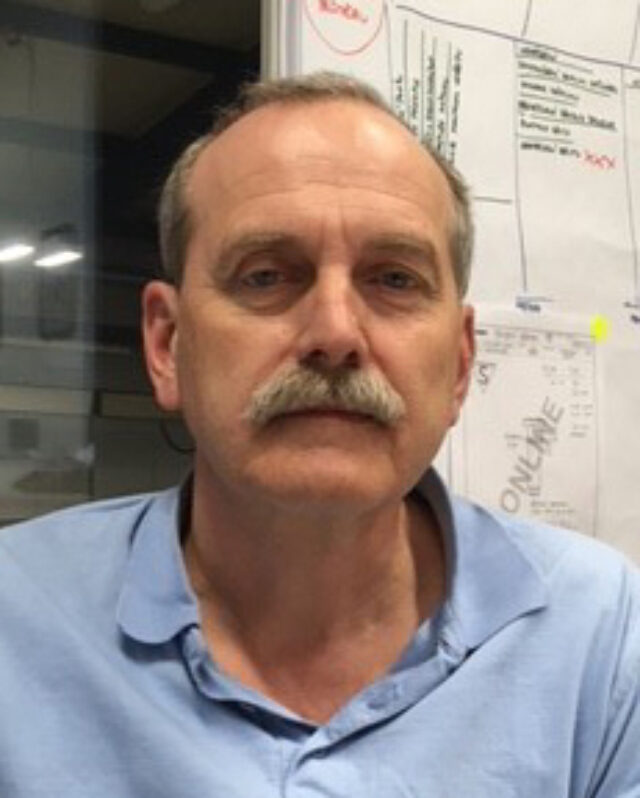

Martin Mach joined KAMAX in Turnov in August 1996 as a toolmaker. Two years later, he began working at the Secondary Operation (SO) where he has been working as a manager until today. He was at the very beginning of the machining factory in Turnov and is the best person to describe what each period demanded from employees. This summer, he will be involved in setting up the first robotic workplace in Turnov.

What was the situation like when you started in 1996?

"At that time we had 16 people who kind of knew what to do, but were not sure how or with what. Through a trial and error approach people laid the first “building blocks” of the machining technology in our shop. We knew nothing about turning technology, centreless grinding or thread shaping. Our workers were trained only once. These were hard times and we suffered from a lack of knowledge and experience with machining technology as this knowledge was necessary in order to work on semi-finished products. We did not have qualified staff and we did not understand to operate the machines that were moved from German plants to our factory. These machines were 20 years old or sometimes even older."

How did you manage to survive these conditions?

"The pilot parts for us were KX7780 and KX7299 (Wheel bolts). We used these parts to learn how to turn metals, how to use centreless grinding and milling. More and more workers eager to learn new techniques and wanting to improve were constantly joining our company. Gradually, these workers became the future machine adjusters, shift masters and operators who learned to master the technology. It took us about ten years to recruit and stabilize our staff and feel confident to say that we understand machining technology."

1999 was a milestone for Turnov, why?

„In 1999 we began using the first hand-loaded CNC lathes. We had no experience with machine programming so we needed support from an external company. Later, thanks to personal interest and self-study of Mr. Lukeš we were able to take over this activity. Mr. Lukeš is rightly seen as the founder of CNC programming and turning technology in Turnov.“

When did automation start at SO?

„The process began in 2008: hand-loaded machines were replaced by new, automatically-loaded machines, which greatly increased our performance. Using new machines required us to explain to our employees why and how defects occur, what needs to be checked at regular intervals and what needs to be cleaned and changed. We started working with operators and adjusters in teams and we shared and discussed problems and eliminated mistakes. The basis of a well-functioning workshop is trust and the art of listening. Only then it is possible to lead a team of workers well and to achieve the necessary development. Cooperation between shift masters, fair play, a good mindset and a positive approach and acceptance of new challenges and changes are the necessary elements of success.“

What developments are in store for the near future?

„Currently, we have 51 machines in our machine shop. Only 4.5% of the machines are manually loaded, 95.5% are fully automated. The culmination of the current development is the installation of the first robot, the so-called robotic arm which will be used for loading parts into the LYNX machine. This shall occur in July. In addition to the loading and unloading handled by the robotic arm, the workplace will be equipped with a measuring unit which will check the specified turning dimensions. For us as the users of complex technology, this means again that we will need to adopt and handle new and unknown systems.“

KXpress · 2021 | 01