Back to the workshop

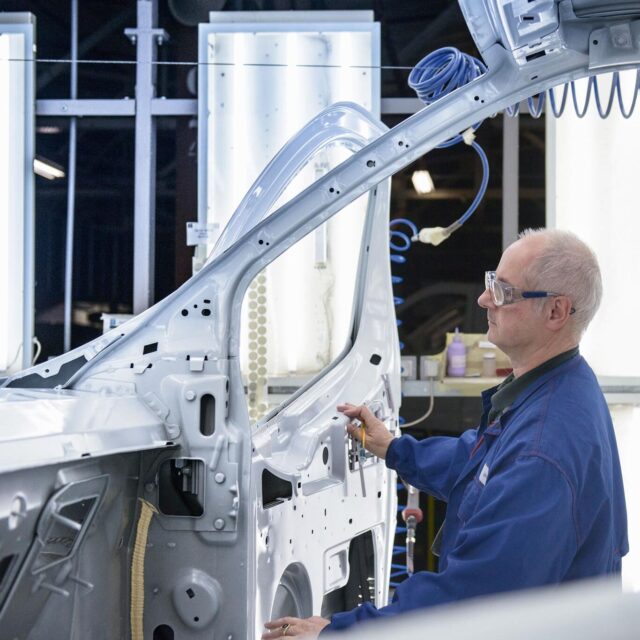

Dangerous airbags, defective brake lights, damaged transmissions, incorrectly programmed software: Millions of vehicles around the world have already had to be recalled to workshops in recent years due to such safety defects. The automotive industry has been one of the sectors with the highest number of recalls worldwide for years. We can read in the media almost every day which models of well-known car brands are being ordered back to the workshop for quality reasons – and in most cases parts are being replaced. With this in mind, it is all the more important for us to pay careful attention to quality to ensure that we do not end up being responsible for a recall.

Between 2011 and 2020, 331 million vehicles were recalled to workshops in the USA alone due to safety defects. According to a study by the Center of Automotive Management (CAM): More than twice as many vehicles were recalled than new cars were sold during the same period. These recalls often take place as a precautionary measure, there are also always cases in which genuinely serious safety problems can arise. After all, in a worst case, a malfunctioning part in a vehicle can end up costing lives.

The figures show that this trend of high recall numbers is continuing worldwide. The risk of such major recalls has increased significantly due to cross-brand and cross-model manufacturing processes and global production networks. When a defect does occur, it can quickly impact different models and also be found in more than just one car brand. Other causes of growing quality problems include the increasing technical complexity of cars, shorter development times due to intense competition, and high cost pressure. Experts are already predicting that problems with battery systems and software problems will increase significantly.

As consumers, though, we are becoming progressively less aware of recalls. This is also the reason why the number of vehicles that are actually taken to the workshop is nowhere near the number of vehicles affected. Because such recalls are so frequent, people have become somewhat accustomed to them.

What exactly is a recall?

Products that pose a potential risk to human and animal health are recalled by companies and requests are issued to return them so that the quality defect can be rectified. Media are used for this purpose and companies provide information on their own websites as well as via social media. Authorities are always involved in such recalls, because there are clear legal requirements on how to deal with an unsafe product. Such recalls are usually carried out voluntarily by the companies after consultation with the authorities.

Recalls are expensive

One of the largest recalls in the auto industry involved defective airbags. At least 19 manufacturers worldwide withdrew a total of around 70 million vehicles from the market. In this case, it was possible to observe a “domino effect”. Given the use of extensively used components, a single recall can therefore have serious consequences for an entire industry. This is not just about the cost of the recall itself, but time and again also about the cost of rebuilding a company’s reputation. At the same time, we should always keep in mind that our products are also installed in vehicles from nearly every automobile manufacturer.

Average Value of large product Recall claims

Automotive/industrial supplier

€12.4m

Food/beverage

€7.9m

All sectors

€10.5m

Recalls are often caused by suppliers

The search for the cause begins as soon as a defect is detected by an automotive manufacturer. It is not uncommon for defects to be suspected at supplier. When this happens, suppliers bear the burden of proof. It is essential to have a functioning quality management system that documents as much as possible and makes it almost seamlessly possible to prove the conformity of one’s products. Because in the end it comes down to this: Who is going to pay for the damage?

The most important thing up front: We have insurance coverage when something like that happens. But recalls almost always involve a high deductible, and quality defects end up costing us both money and customer satisfaction. Last year we had a case in the United States for one of our products that was delivered to our customer General Motors. The strength of one part of our bolt was not meeting spec. The deviation, however, was not particularly high. With a normal tightening of the torque, this was only noticed on the customer side after a longer period of time.

During the error analysis, at first glance all our quality documents were flawless. At first glance, no defect was visible. After extensive internal investigations, a chain of circumstances was identified. This involved software errors or conversion, the FIFO principle (first-in-first-out in warehousing) not being adhered to, and other supposedly small deviations that had added up in the end. This not only led to a deviation, but also to the affected production batch stretching over more vehicles than would otherwise have been the case. However, we were able to prove in subsequent tests that the risk was very low.

DISTRIBUTION OF PRODUCT RECALLS BY INDUSTRY

Automotive/industrial supplier

Food/beverage

IT/electronics

Retail

Manufacturing/packaging/metal processing/industrial machinery

We are also affected

Despite these findings, our customer decided to recall the affected vehicles. This is a development that we can observe throughout the sector: Cars are being reworked ever more quickly and comprehensively, and the costs are being passed right back to the suppliers. This case was relatively minor, but it still resulted in a damage of $3 million.

We are also currently handling a claim with one of our most important customers. There is a possibility here that parts from our plant in Turnov (Czech Republic) were delivered with quality defects, and we may have to contend with significant costs. The analysis of the defect is very complex and ambiguous, however, and we are currently still in discussions with the customer and our insurance company.

On the next two pages, you will find out what efforts we are making to prevent such cases from occurring in the first place.

KXpress