Look who’s bringing the bolts!

We recently welcomed three new colleagues of a special kind at our plant in Wujin. We have decided to call one of them “ Wall-E”. His mission, however, is not to clean up the earth and, unfortunately, he bears little resemblance to the original. If you were to ask Wall-E what his strengths are, he would no doubt say something like: “I’m really good at transporting things from point A to point B.”

But Wall-E can do so much more than that. He helps us to lower the number of accidents and relieves us of heavy work. And he lets us experience digitalization and innovation. Wall-E is one of three Automated Guided Vehicles (AGV) – basically an automated truck.

For our colleagues in Wujin, the little helper is not only a relief, but also introduces some fun into the work day. “It’s exciting to watch the vehicles. Forklifts are one of the biggest risks for accidents in our plants. We can significantly reduce these by using the AGVs,” says Songhe Xu, who as Supply Chain Manager oversees many digital projects at the plant.

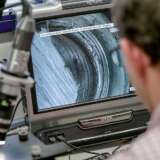

Wall-E drives along predefined routes to the “pick-up” and destination stations for the transports. These act as a kind of “bus stop” where the vehicle picks up and delivers parts. The stops are marked by yellow boxes and guidelines on the floor. The forklift is oriented based on sophisticated laser technology that guides it along the routes. The technology behind this may be familiar to some from vacuum robots at home. The small robot receives orders through a central management system. It can be easily controlled by photoelectric signals and the new SAP system S4/HANA.

PRAGMATIC SOLUTION

“Automation projects are usually extremely complex. In addition to the vehicle, the IT infrastructure in the plant must also be compatible with such solutions,” Songhe explains. “There are probably even smarter solutions on the market. It was important for us to take a step further toward digitalization now. We need to take a much closer look at such solutions. This helps us strengthen our digital mindset and present ourselves more innovatively to customers. It is important to think outside the box to find creative solutions. AGVs are a pragmatic solution with a big impact. It takes a bit of courage to introduce them. With the new smart helpers, we have expanded our playing field for the future with a comparatively small investment.”

Wall-E and his friends can work for an average of about 6.5 hours every day. Then they have to return to their charging stations. Their support results in less waiting time between production areas, and they are also very attentive: they use digital tags instead of paper labels. This makes it easier for our new team members to check their to-do lists. Wall-E also helps us to operate more closely in accordance with lean production. It can only transport boxes from the floor; it cannot handle larger stacks of boxes. This means that production must be as accurate as possible to customer demand and inventories minimized. The vehicles can also be customized to suit the application and environment.

“We are pleased to have been able to implement this project in Wujin so quickly and are always available for consultation,” says Songhe Xu.

KXpress