All products and tools in a single system

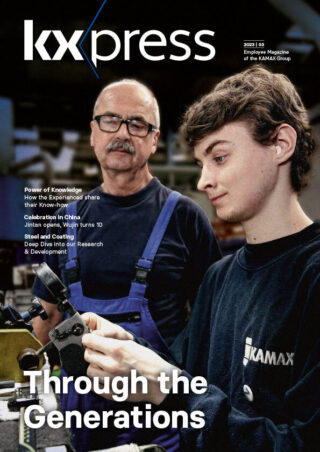

Transferring knowledge between our locations and between new and old colleagues is a challenge. What would it be like if all the technical information in the KAMAX world could be found in one place? If all of our locations were able at any time to access the latest data for manufacturing their products? Sounds like a perfect world. Now, with Teamcenter and NX, we are one step closer to achieving this.

Teamcenter is software that allows companies to store all of their product information for the entire life cycle – from the initial concept right through to end-of-life scrapping and recycling. NX is the corresponding design software that creates a digital twin of each product. Major customers like Daimler are already implementing their jobs entirely through Teamcenter.

Turnov to be fully integrated

The software features a different user interface for each user. Machine operators can see the things that are important for their work – such as jobs that they can send directly to the machine. Designers can delve deeper into the content and make changes. Internal rules and guidelines are saved in the system.

Over the past three years, the project to integrate all locations into this system has been accelerating, and we are currently working to integrate the plant in Turnov (Czech Republic) in the first quarter of 2024. Once this has been done, all of the locations in Europe and Asia will be fully connected to Teamcenter and NX. The long-term goal is to pool all of the Group’s technical expertise in a single place. Doing this also entails transferring Key Tech (the predecessor system), which is still running in parallel. Damiano Klug, Team Leader of Software Engineering at Tools & Equipment: “Any time that our colleagues have to use multiple systems to find the information they need, it automatically slows things down and complicates the process. The sooner we can work with just one system, the better.”

The five phases of product development

“We’ve got to get used to it”

Teamcenter and NX are key components of digitalization and automation. Their use saves time and reduces costs. How? One way involves closed loop manufacturing (CLM). Here, a press automatically compares a manufactured screw with its digital twin in Teamcenter and NX and identifies any discrepancies. In the best case, the machine is itself able to change the production parameters and solve the problem.

Are there any obstacles? Damiano Klug: “Working with Teamcenter requires a different way of thinking, and we still have to get used to that here at KAMAX.” One example is the search function: extremely precise requirements must be entered for a screw – otherwise, the system will output too many results. Damiano Klug and his team are currently working to train our colleagues worldwide in this very area. “I see myself as a facilitator, and I want to share my enthusiasm for this software with my colleagues around the globe and show them the benefits it offers. The system should be tailored to KAMAX processes.” Once everything is in place, our shared use of Teamcenter NX will create uniform access to, and use of, product information throughout the entire life cycle of a product. This will also make it easier to transfer knowledge.

… are already classified in Teamcenter.

… are already classified in Teamcenter.

KXpress