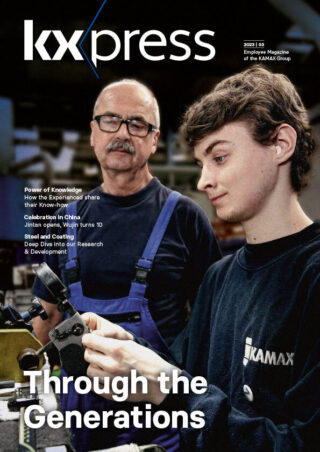

From screwdrivers

to e-bike motors

In 1948 in the basement of his house, Robert Schröder established the eponymous company that has been part of the KAMAX Group since 2021. Something that began with the production of turned parts for the local lock and fitting industry in Wuppertal (Germany) quickly grew to comprise new technologies, business fields, and locations. In 2023 the company is celebrating its 75th anniversary, and the Casel family has been part of this story since shortly after the company was founded.

André Casel

Today, André Casel is the Managing Director of Robert Schröder, his family has been a part of it for many decades. His father joined Robert Schröder as an electrician in the mid-1950s. It was about the same time when the company began producing tools like hand drills, thread-cutting tools, and drill screwdrivers. Casel: “The technologies that we mastered back then – reaming, centerless grinding, thread rolling, interlinking – allowed us to enter the complex part business in the early 2000s, including for power liftgates and e-bike components.”

Milestones in the company history

- 1948

Establishment of Robert Schröder KG

Production of custom turned parts for the local lock and fitting industry - Middle of the 1950s

Production of hand tools for the first time, including drill checks and hand drills, and then thread cutters and drill screwdrivers later on.

This involved the introduction of technologies like reaming, centerless grinding, thread rolling, and interlinking

Herbert Casel joins the company

Production area continuously expanded to accommodate growth - 1978

First six-spindle automatic lathe - 1980

Herbert Casel becomes Managing Director and shareholder - 1995

André Casel joins the company - 1997

The Casel family acquires more than 90 percent of the shares in Robert Schröder - 1998

Location opens in Bydgoszcz (Poland) for turned parts from Eastern Europe - 2000

Production of cold-formed parts begins using a Hatebur AKP3-5 at the location in Bydgoszcz - 2000

André Casel takes over management of the company - 2001

First CNC – six-spindle machine - 2005

Acquisition of Hein&Co for a significant entry into cold forming, investments in six-stage cold forming machine - 2008

Entry into production of spindles for power liftgates - 2012

The tool division is sold to Peddinghaus - 2015

Entry into the production of e-bike components - From 2015

Significant increase in the combination of cold-forming blanks and complex further processing - 2021

KAMAX acquires a majority share

The future was clear

Robert Schröder has continued growing to the present day. In 1980, Herbert Casel became Managing Director and shareholder, and Petra Casel – currently the company’s Commercial Director – began her traineeship at Robert Schröder in the same year. André Casel joined the company in 1995. It was somehow clear, even in the beginning, that he would take over from his father as Managing Director one day. Already at the age of four, he could be found roaming through production and asking to be allowed to operate the machines. That is why it is unsurprising that both his parents and the company’s founder, Robert Schröder, put their faith in him. André Casel’s entire training – including an apprenticeship at a key machine supplier and a degree in mechanical engineering – took place with this goal in mind.

This was certainly helped by the fact that Herbert Casel saw that his son could gain his own experience. His son remembers: “He told me that I was crazy when I purchased multiple machines at once.” At the same time, he was glad that he no longer had to conduct negotiations with purchasers himself and could pass on this responsibility. Casel: “He always trusted me.” Things stayed pretty much the same in the KAMAX Group, and Casel attaches great importance to an open and constructive dialogue with the Global Executive Board (GEB).

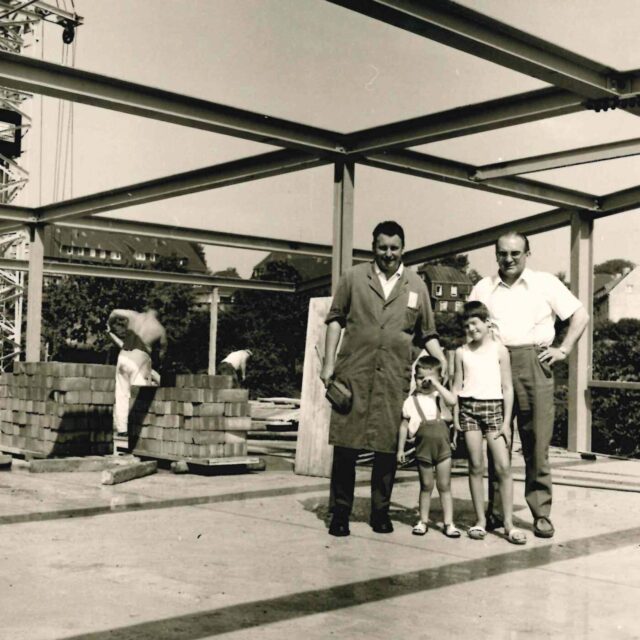

At the very beginning: construction of the first company buildings

Young André Casel (center right) with his father and founder Robert Schröder

Project with plant in Mexico

Robert Schröder’s agenda for the future includes internationalization and technical development. An initial project that is already underway involves the production of spindles for power liftgates at our plant in León (Mexico). While the team at Robert Schröder continues to offer technical and sales support, plans call for this business area to operate independently in the future. Operations may even be expanded to Asia. The company is also looking to develop on the technology side. In addition to gear parts, the goal is to supply assembled units. Casel: “I like it best when we are able to utilize many different technologies for products. Starting out with cold forming, for example, and then continually refining the process. Deep down, I’ve always been a technician, and I always will be.”

KXpress