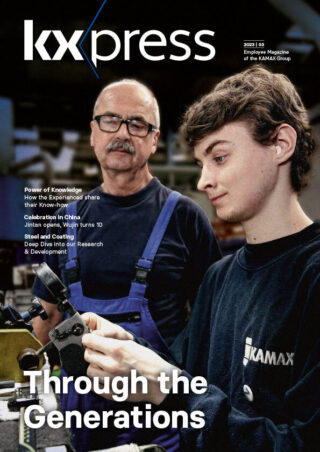

Learning through generations: how we pass on knowledge

Already in the seventeenth century, English philosopher Francis Bacon recognized that “knowledge is power.” There is also a great deal of knowledge at KAMAX. The knowledge that employees bring with them, develop, and pass on contributes to the long-term success of our company. In particular, it is the passing on of this knowledge that is so important today, especially because at some of our locations, many of our colleagues will be retiring over the next few years.

A glance at the figures is enough to illustrate the scope of the challenges we will be facing in the not-to-distant future: more than 32 percent of KAMAX employees worldwide are older than 50, and 9 percent are over the age of 60. What can we do to make sure that the people who follow them have the necessary expertise? Luckily, we have the chance to plan ahead, because we generally have a pretty good idea of when our colleagues are going to retire.

Higher fluctuation rate

The working world has changed: in the past, when someone went to a company to learn a trade, they generally stayed there. Spending your entire life with a single employer was the standard, rather than the exception. As the years have passed, this model has changed. People have become more mobile, and the opportunities for training and professional development have increased. Even when these things are possible in their “own” companies, many people now decide to change companies more frequently. And not just at KAMAX. The gaps that this creates can also be felt on a personal level; even so, it is important that we can continue to operate at the same level so that we can maintain our company’s success.

“Training employees is about increasing their motivation to take on more challenging tasks!”

José “Pepe” Puchau, Director Engineering in Museros (Spain)

In other words, the combination of age structure and staff fluctuation has made it necessary to safeguard the store of knowledge that exists within our company. Various approaches have arisen at our locations to help us pass along the knowledge and expertise of long-standing employees. One example: Jeff Kollhoff Sr., who joined KAMAX in u. He started out as a Thread Roll Operator at the plant in Lapeer (USA) and gradually worked his way up. In the past, there was a high fluctuation rate in the “thread rolling” department, and it was difficult to find new employees. This resulted in the company hiring contract workers from other countries.

Experienced hands show how it’s done

In early 2023, Jeff Kollhoff developed a training program for newly hired Thread Roll Operators – at this time he trained a younger colleague, Diego Martinez, who can conduct the introductory training for thread rolling in Spanish. Martinez came to the USA from Venezuela and was hired as a Thread Roll Operator. This gives us the opportunity to expand our reach to the growing Spanish-speaking population in the area around Flint, where the Lapeer plant is located. Thanks to the work of experienced experts like Jeff with these up-and-coming talents, we are now able to train employees that we would have been unable to utilize in the past.

Another Spanish-speaking colleague who is currently traveling through the KAMAX world to share his knowledge is José “Pepe” Puchau. Over the course of several decades with our company, he has built up an amazing amount of technical expertise at our plant in Museros (Spain), and he has been sharing this know-how not only in his own country, but also with our teams in Slovakia, the USA, and Mexico. This is done across multiple departments and includes broken tools, standardization, or even just the fundamentals of cold forming. “Training employees is always about increasing their knowledge, but there is something more important: increasing their motivation to take on more challenging tasks, improve quality, and strive to do things a little better every day”, says “Pepe” Puchau.

Proportion of employees over 50

Retirees help out

In Homberg (Germany), experienced colleagues are being placed alongside young colleagues and those who are relatively new to the firm so that they can help them with their knowledge of particular work topics. The tempering/quenching, cold forming, and secondary operations departments are all employing people who have already retired. These people can help out at short notice or are signed to temporary contracts that allow them to earn a bit of extra money. Because they are not tied to a fixed schedule, they can be deployed without much lead time. Someone who does not have a problem with doing regular night shifts is therefore able to relieve the burden on many permanent employees, allowing them to switch to the early or late shift.

But flexibility is not the only thing they offer: these part-time workers’ extensive expertise benefits the entire department. Training has also been modified to address the age structure and combat the loss of knowledge. A good example is offered by machine and systems operators in tempering and quenching: apprentices now spend the final six months of their training entirely in the department, and even their final exam takes place directly on the machine. Things were different in the past. The new approach deepens technical expertise while fostering ties to the department so that these newcomers are more likely to remain there.

Retiree in Homberg helps out

Wide-ranging training

Another example of a wide-ranging training concept is the plant in Turnov (Czech Republic). There we have various cooperations with local schools, where we train their pupils and students regularly at the plant, usually for a year. Students are trained in CH, SO, or the Toolshop – depending on their field of study. They learn basics from the theory of (cold) forming, and machining, and then of course they get to know the machine itself. In the best case, we then take them on, like Filip Drbohlav, who was trained by instructor Jiří Lukeš [see the cover of the magazine].

At Tools & Equipment in Bardejov (Slovakia), we rely on a training matrix to supply new employees with knowledge of various systems at an early date. “We draw up a qualification matrix for every employee. This directly accounts for successive training on multiple machines. As a result, people are given the potential to step in where needed right from the start,” explains Katarína Horváthová from the local People & Culture department. Experienced colleagues are also assigned to work alongside newly hired people and newcomers so that they can learn as much as possible from them – an approach that has already proven its worth at other KAMAX locations.

In other words, the situation is similar wherever you go: experienced colleagues are called upon to share the knowledge they have gained over their decades working at KAMAX with the next generation. This isn’t always easy in day-to-day work, and it can even be frustrating, particularly when new employees end up leaving the company quickly. At the end of the day, however, the tireless efforts of people like Jeff Kollhoff and “Pepe” Puchau to pass on their expertise on a daily basis are necessary if we are going to prepare a new generation and get them excited about their work.

KXpress