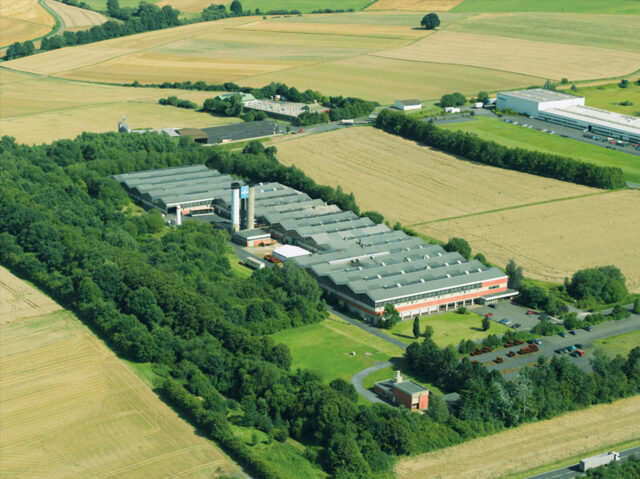

Aerial view of the Alsfeld plant

Solidarity and cooperation to the end

Our plant in Alsfeld (Germany) is closing its doors for good at the end of June. Around 40 employees will be transferred to other plants and a fair transitional solution has been created for the other employees. Nevertheless, the plant closure hurts. We look back at the 50-year history of the site, the special cohesion and the reasons for the closure.

WHAT HAPPENS TO THE EMPLOYEES?

Of the original 200 employees in Alsfeld, around 40 will be taken on at the Homberg and Osterode sites. At the same time, KAMAX has arranged a fair transitional solution (known as a transfer company) with support of the works council and the union. More than 80 colleagues will continue to be paid at 80% of their salary for up to one year, receive a budget of 2,500 euros for further training, as well as professional support in finding a new job. Other employees have already resigned on their own, or are retiring, or taking early retirement. Regardless of this, each employee receives a severance payment based on years of service, age and number of children, among other factors.

History repeats itself. Some were there themselves, many do not know: The plant in Alsfeld – was founded in 1970 to supplement production at the headquarters in Homberg 30 km away. In 1994 it closed due to economic difficulties. Some of the employees continued on their own and independently took over the old machines on the factory premises (in the departments of heat treatment and phosphatizing, among others).

In 2001, KAMAX decided to restart production in Alsfeld (not as its own plant) but to supplement production in Homberg. This was because demand for bolts was rising significantly and there were capacity bottlenecks. Many of those who had already worked there in previous years were happy to return and become part of the project. Around 40 people were employed in Alsfeld during this period. The decisive character at the time was Anton Kreuter. Due to the comparatively small number of employees, a special team spirit developed; a well-rehearsed team with mutual trust and an appreciative atmosphere. This did not change when the number multiplied within a few years. The reason for the growth was the decision to relocate especially long and heavy parts back to Alsfeld.

“In my early days, everything was done to relieve the production in Homberg, even under the most difficult circumstances. It was already a tight bunch back then, and the solidarity is still what I remember about the Alsfeld plant and its people today.”

Uwe Breves,

PRODUCTION MANAGER ALSFELD (2001 – 2011)

Typical for Alsfeld: the production of long and heavy parts

SPECIAL ATMOSPHERE

“The team spirit was always particularly strong here, even back in the 80s. It was a great place to work. The family atmosphere has always distinguished Alsfeld. That’s why I was very happy to start working here again after 13 years,” says machine operator Klaus Adler, who was among those who returned in 2006 after a long absence. At that time KAMAX also made the decision to re-establish Alsfeld as an independent plant – and not just as a supplement to production at the headquarters.The plant quickly developed from a place that shortly before had had neither sufficient lighting conditions nor a functioning heating system into an integral part of the corporate group. Just one of many reasons why employees proudly wore the KAMAX jacket outside of work.

“I didn’t leave Alsfeld with dry eyes. When I came, my expectation was that I would have to spend at least a year to learn the ropes and gain acceptance. I didn’t know the language very very well and I was still young. But the openness to accept me surprised me in a very positive way. We were like a little family.”

Tomáš Hájek,

PLANT MANAGER Alsfeld (2014 – 2016)

With the help of young managers – including Tomáš Hájek, now plant manager in Turnov (Czech Republic), and Jose Garcia, now plant manager in Homberg – Alsfeld continued to optimize many of its processes in the years that followed. Without having to ask them to do so, the long-established employees made this possible by placing a great deal of trust in and supporting the newcomers.

However, from an economic perspective a challenging future could already be expected for the site at that time. Not because of the performance of the workforce, but because the by comparison material-intensive production of large parts was becoming increasingly expensive due to high steel prices. Additional the new business was stagnating. Added to this were constant demands for price reductions from customers, which continue to this day. Despite this, KAMAX decided to maintain all German sites with the new strategy in 2019, hoping to stabilize and develop the plants together. The COVID pandemic then delivered one of the toughest incisions in the company’s history. Our customers stopped production, and the Alsfeld plant made a loss of around 4 million euros in 2020.

“The performance that the employees here have shown, especially in recent months, is anything but self-evident. Actually, we’ve been getting new responsibilities every month or two lately, and we’ve had to constantly adjust.”

Dennis Winter,

PLANT MANAGER Alsfeld (2022)

LITTLE GROWTH EXPECTED

Even before this crisis, it was clear that KAMAX urgently needed to adapt to the new conditions in the automotive industry. After all, up to 30 percent of the German product portfolio is at risk due to the switch from combustion engines to electric motors run on. And a 1:1 replacement with new parts is not easily possible, although the Sales, Business Development and Technology departments are doing a good job in this regard. “Europe is not a growth market, unlike the USA and China,” explains Christian Wolff, VP Finance & Controlling. Price wars are particularly fierce, and rising energy and resource prices are doing the rest. In order to be able to survive in Germany in the future, massive investments in all German plants are needed and will be needed in the future, as envisaged in the corporate strategy. The losses caused by the pandemic and the tighter forecasts meant that all investments were no longer possible. Sticking to the original plan would have jeopardized the entire production in Germany when in doubt. So in the end and with a heavy heart, the decision was made not to continue operating the Alsfeld plant in the medium term.

A decision that led to much disappointment, not only at the Alsfeld site. A labor dispute followed, high fluctuation and periods in which the remaining employees were required to work particularly hard. And despite everything, as in the decades before, the workforce performed far beyond what was expected. “They gave their all every day. It’s actually incredible what was achieved here right up to the end,” emphasizes Lukas Freidhof, head of the maintenance department and the production areas cold heading, heat treatment and maintenance.

Pictures from the production halls in Alsfeld in March, when it was slowly getting emptier

In the end, all other colleagues can only take a bow before all Alsfeld KAMAXians. Only very few can empathize with what it meant for the employees to close the plant. The Alsfeld plant was and is a matter of the heart for many. In particular, it is the community that has shaped the site to the end, and through which a mutual loyalty has developed that cannot be taken for granted. It should be the concern of all of us not to forget the people and the achievements of the site’s 50-year history and to remember them as a special part of our corporate history.

Long-standing employees from Alsfeld who have many stories to tell and know what has distinguished the location over decades: cross-generational cohesion!

KXpress