EFFICIENCY – MODULAR TOOL SET

More flexible and faster toolmaking

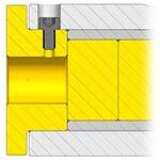

The gray areas will be built modular in the future.

Tools & Equipment has been relying on consistent standardization and modularization for years. This allows the entire business process to be digitized and automated. The result: Faster to the tool you need!

Some of the employees are already familiar with the fully automated production of telescopic dies, which enables higher quantities and an extreme shortening of the delivery time. This means that the die can be removed from the production line just a few hours after entering the desired parameters.

However, while up to now only the inner components (dies) have been modular in design, this concept is now being extended to the entire tool set. The goal is that for 80% of our products it will be sufficient to enter the part geometry and the intended press in order to start the automatic production of the die. In the case of repeat orders, the components are then already digitized and all the machine operator has to do is scan the tool number and trigger the order. In an emergency situation, the delivery time could then even be specified to the hour.

The patent has already been applied for and the investments for the steel part production have been approved. The only thing missing is the tool, but soon not anymore!

How do you like this article?

KXpress · 2021 | 02