Plant Manager Wilko Hinrichs-Stark in conversation with Peter Reinke (CH)

The founding location on the way to the future

No matter where you look, one thing gets obvious: there’s a lot going on. Construction workers are crawling across the roof of the plant, diggers are ready for action and fresh concrete is lying in holes dug in front of the buildings. New machines are arriving at the plant regularly, and for reasons of space there are tents and truck trailers parked outside to store parts temporarily. Where our company founder Rudolf Kellermann kept his horses 70 years ago, is now the main warehouse. It is slowly getting crowded on the operation premises in Osterode or to put it in figures: The ratio of logistics storage space to order volume is 45 percent smaller than two years ago. It is the result of what plant manager Wilko Hinrichs-Stark likes to call an “open-heart surgery”.

Picture from a time when Osterode was still dependent on the help of horses for machine relocations

That is, because in 2021 and 2022 the founding location is undergoing the probably biggest changes in a long time. The two main reasons for this: the PPA project [more information: One of the biggest KAMAX projects …] and the investments associated with it, as well as a significant rejuvenation of the management team – not least at the position of plant manager. The KAMAX Group is investing a total of around 22 million euros in the plant in 2020/21. location. The money will be used to carry out necessary renovations, to accommodate relocated machines, and to expand the capacity and innovative strength of the operation. This is a step that by no means all employees in Osterode had expected.

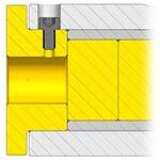

PPA SPECIALIZATION:

Dimension range “M16 and larger” as well as KXtreme parts & Eccentric bolts

NEW HALL IN PLANNING

However, the commitment to the location is also a major challenge for the almost 350 employees. Because, as everywhere else, the PPA machine relocations and restructurings have to take place during the ongoing production process. “What in the past would have been one major project, we now have to get done on short notice and in addition to all the everything else,” explains Sven Urban, OPEX Manager. Plant manager Wilko Hinrichs-Stark puts it differently: “All our employees can be proud of what has been achieved here throughout the last year!”

Space for innovative manufacturing concepts in the new “Blue Hall” building

Another project is the so-called “Blue Hall” (named after the “Blue House”, which also belongs to KAMAX and is located right next to it). The building permit was issued in November, and the groundbreaking will take place shortly. The new building will be built on a meadow next to the main entrance of the premise. It will create more space to process additional orders and parts. At the moment, this is only possible with difficulty, as the plant is permanently running at its capacity limit.

At first glance, it seems as if Osterode can hardly expect to receive more orders than lately in the next years, since about 40 to 50 percent of the parts produced here are tied to the combustion engine. The advantage though: The founding location supplies these parts mainly to trucks (e.g. Volvo and Scania), which are only affected by the switch to e-motors with delay compared to other vehicle types. Furthermore, two ideal products for e-mobility will be manufactured here in the future, with the production of the “long & thin” bolt for truck battery packs and the specialization on our KXtreme. The ultra-high-strength lightweight part is one of the key innovations of the KAMAX Group and will become even more important in the future. In addition, the plan is to expand in the “Heavy Duty” area. Particularly heavy and large bolts are needed in this sector, for example in construction machinery.

“We have to change. Not because everything was bad, but because the market and the world around us are changing. We have to reinvent ourselves in a way with a healthy combination of fun and sweat. We want to continue to play an important role for KAMAX also in the future, and to do that it’s just as important that everyone comes to work in the morning with a smile.”

Wilko Hinrichs-Stark,

PLANT MANAGER IN OSTERODE

MUCH EXISTING POTENTIAL

Osterode has the potential to successfully tackle all of these developments. In over 85 years, a great deal of know-how has been built up that the employees use every day. In addition, the company is proud to be the founding location. With plant manager Wilko Hinrichs-Stark, the culture is also changing. The management team has been significantly rejuvenated, and the focus is now on strengthening the team spirit and working together as a team to pave the way for being a pioneering plant within the Group.

Every Monday to Thursday morning, the management team has blocked one and a half hours in order to go through the production together. When you are going round with the plant manager, he greets each employee personally, machine operators approach him on their own initiative to talk about current developments. Everyone has the chance to get involved – that is the wish of the management team.

This idea is to be implanted in the minds from the very beginning, the young talents are challenged and encouraged, as the example of Kevin Boettcher shows [see Being Brave]. To ensure a long-term supply of talents, the training sector is a very important pillar. In addition, there is the cooperation with the nearby Technical University of Clausthal, which was already founded in 1775. It holds absolute top positions in university rankings in Germany in both engineering and mechanical engineering. In the meantime, a double-digit number of graduates from there are working at the founding location. Good prerequisites for a successful long-term future, the foundations for which are currently being laid.

How do you like this article?

KXpress · 2021 | 02