Thousands of part numbers on demand

FACIL, Nexineer and the Robert Schröder Group – there are meanwhile several business units that don’t mention the KAMAX brand, but which belong to our company group in whole or in part. 4fastening (abbreviated 4f) also falls into this category. The name is unfamiliar to most people outside Europe. At the European locations, the subsidiary is known to some employees, but only few can explain exactly what the connection to KAMAX is.

When the customer calls, we immediately have over 2,000 part numbers available,” explains Paul Klasen, who is a former KAMAX trainee and now in charge of quality management at 4f. This feature distinguishes the company in comparison to our plants. Whereas at our plant many things are designed to ensure that parts are delivered on time at the end of the production process, at 4fastening they sometimes wait for years in small quantities in the warehouse to be picked up.

Because unlike us, 4f does not produce themselves. As a rule, customers enquire with a request for which several individual parts are needed. The 36-strong team in Pohlheim (Germany) makes it easy for customers, procuring them all and bundling them into one package so that the number of suppliers is significantly reduced. A large proportion of the products for this are purchased from KAMAX. These account for a total of 80 percent. However, the aim is to increase the external share to at least 40 percent in the next few years.

“It’s exciting to see that a lot is happening at KAMAX and at 4f in particular. As the main contact person for a specific group of customers, I am responsible for preparing quotations as well as processing them. I also coordinate these orders with the logistics departments.”

Johanna Brandt,

Inside Sales

“The right organiziation is crucial. The team is relatively small, so I have to help everywhere: Whether it’s picking, driving a forklift or packing. Many truck drivers also come from abroad, for example from Ukraine, Poland or Belarus, so I’m an interpreter at the same time. The importance of communication is often underestimated.”

Valentin Koch,

LOGISTICS TEAM LEADER

In addition, the company also offers warehousing, which means that some parts are stored in the 7,200 square meter hall for a very long time – ready for demand. Mostly this concerns small series, which would only hold up the large-volume production of the KAMAX plants. If the customer calls today, the truck must be able to pick up the stored parts tomorrow at the latest. In total, more than ten employees in logistics ensure that this process runs smoothly.

To ensure that there are no complaints about the products from the customer side, 4f has its own quality department and is currently building a new laboratory. An important investment that gives the comparatively small company another distinctive feature – in addition to the important IATF certification, which is not normally awarded to remote locations without an own production.

“As part of the quality management team, I ensure that the products purchased from our suppliers also meet the claims. We sample them and also accompany the external audits. In addition, we acquire new suppliers who expand the portfolio. The job is particularly fun because there are many interfaces with other departments,” says Marcia Lins, Supplier Quality Management.

If the quality is right, there are only three more steps to go after storage: picking, packing, and shipping the parts. The products are then placed on pallets and loaded onto trucks with forklifts. Well packed, they are then sent on their way – to be installed at the customer’s site.

“There are very different customer requirements in terms of how parts are put together and packaged. Still, you are largely independent in this work, which I like. I’ve been here for over seven years and there’s a really good working atmosphere where everyone is willing to help where it’s needed.”

Hüseyin Önder,

WAREHOUSE SPECIALIST

“The shipping process includes preparing customs documents, exchanging information with service providers such as UPS, and preparing delivery documents for the customer. The mix is particularly fun: I’m not only in the office, but also often out in the warehouse collecting parts.”

Tatjana Daum,

SHIPPING CLERK

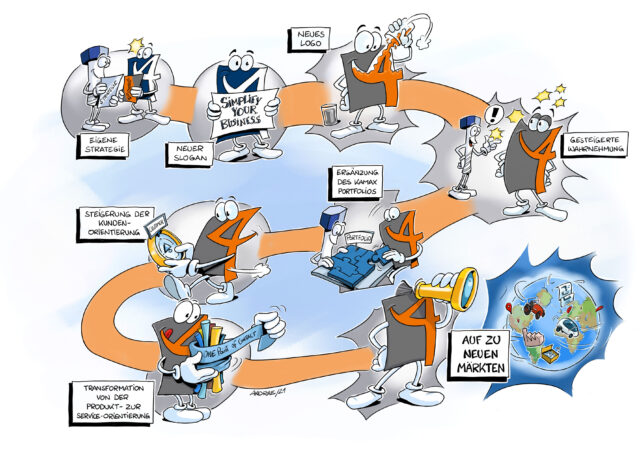

There is an upward trend in the volume of parts shipped: while just under 70 million parts were shipped in 2020, this will rise to around 75 million in 2021. The target for 2022 is as high as 85 million. By way of comparison, the KAMAX plant in Turnov (Czech Republic) ships around one billion bolts to customers. By specializing in smaller product packages and warehousing, however, 4f is pursuing a completely different goal. The logistics service provider was originally founded to relieve KAMAX of the small orders that cost the plants a lot of time. However, Managing Director Patrick Lutz wants more. One important mission is still the completion of the KX product portfolio. But not only: More and more parts from other suppliers in other industries are to be added in order to become attractive for new customers as well.

Patrick Lutz, Managing Director of 4f

“The whole team is fired up to take 4fastening forward. We have realigned ourselves, have our own strategy and roadmap. The warehouse is being expanded and we have a new team of leaders,” explains Patrick Lutz, who himself worked for KAMAX for many years. “There is a lot of motion and we hope that in the future we can work even better with the whole company group and contribute to our joint success.” The path to this goal is ambitious. In as little as three to five years, the aim is not only to acquire new suppliers and customers outside the mobility industry, but also to leave the first footprints in Asia and the Americas, in order to deliver bundled product packages there. The course for this has been set.

How do you like this article?

KXpress · 2021 | 02