Turn old into new

KAMAX Museros has been involved in the recycling of old tools for many years. Due to the change of parts in the automotive market, carbide tools are now obsolete - so many of them remain unused in storage. The plant worked a lot with carbide manufacturers like METASA in the 1970s and 1980s. As a result, the machine shop now has many employees who are trained to work on these tools. This is crucial, because the reuse of obsolete carbide requires highly specialized technicians who are properly trained.

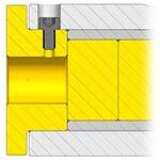

In the Museros workshop, two types of work are distinguished: The first is to carry out repairs on tools currently in use in order to avoid machine downtimes. This is done during the ongoing production process, both for carbide and steel tools. The second task is to prepare tools for new parts. For this purpose, the old carbide models are used. These are all stored in one place, the so-called "pool". When an obsolete tool is taken from there, the technician works on it, gives it a new number and then it is used for the production of new bolts. Currently, many reconditioned tools are used for the PPA project in order to quickly process and manufacture new parts that will be installed in the facility.

The recycling of obsolete tools in Museros has two main reasons: On the one hand, costs are saved, since purchasing new material would be more expensive. In the 1990s, tooling costs were about 7 % of the plant's sales. Currently, there are months when costs drop to almost 2 %. Thus, the plant has been able to save significant money in recent years through the know-how of its employees.

Meanwhile, however, there is a more important second reason besides savings: speed. The goal is to provide tools as quickly as possible to reduce the waiting time for the customer. Thanks to the expansion and modernization of the machine shop, it is now possible with the help of software ("KXinfotool") to quickly find old tools in the "pool" and start working on the carbide within minutes.

"The average price of a tool is over 200 Euros, so it quickly adds up to a relevant amount that we save every year. But I must stress that speed is the crucial point for us," explains Federíco Martínez, head of the machine shop in Museros. "However, the question that concerns us most is: why do tools break and need to be replaced in the first place? The necessary improvement lies in the answer to this question. We will continue to do our best to make our tools as durable as possible."

How do you like this article?

KXpress · 2021 | 02