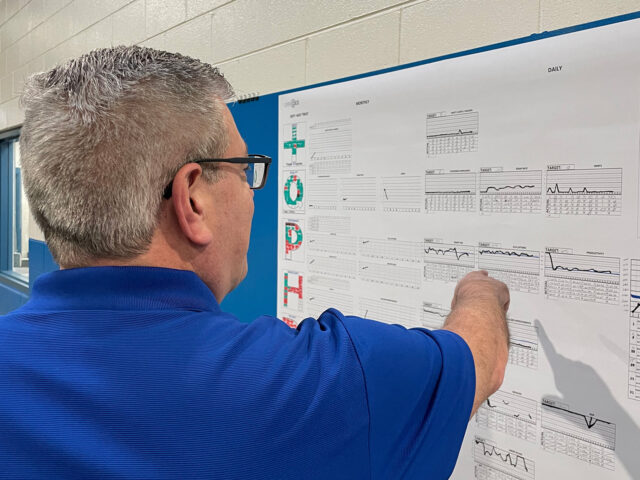

A Moment

with Mike …

The newest addition to the Global Management Team and Lapeer Leadership is Mike Zimmerman. He joined KAMAX in November of 2021 as the Vice President of Americas Operations and Managing Director of Lapeer. We sat down with him and talked about him and his eagerness to improve our operation.

What attracted you to KAMAX?

The people and product. I was familiar with KAMAX because I was previously president of a supplier. I always had good experiences with the employees and they were excited to make changes. Once I learned about Mark Hilfinger’s strategic objectives to standardize and align the operations, I knew this was the right opportunity for me. As a supplier, I was familiar with some of the operational struggles they encountered. Pairing my drive for improvement with the KX spirit of solving problems, I knew I could help align a common goal.

How have your previous experiences prepared you for this leadership role?

I have always been involved with operations and specifically focused on Lean and Continuous Improvement ideology. When I wasn’t influencing change, I dreamt of being able to make those changes. Which also explains why a former company President and consultant is now back at improving operations.

What are your Goals for the year?

It is easy to see we need more training on processes, connected processes, and process discipline. Overtime, we deviate from the standard. The most helpful task in identifying that issue was spending the first six weeks meeting every employee on every shift in the Lapeer facility. There are many great activities on improvement. However, as a leadership team, we have lost focus on helping our associates make parts. We need to prioritize “back to basics” with clear roles and responsibility. Once we have alignment and communication, the processes, their discipline, and structure will quickly fall into place. I am excited to position KAMAX Lapeer as the “Most Efficient KAMAX Facility”, in the future.

Zimmerman’s “Lean Journey” continues to develop with every role. He has earned multiple certificates, two Masters degrees, and spent extended time in Japan with leading experts in Lean systems. “Lean” means “continuous flow of material and elimination of waste in every step of that flow”. In order to achieve that, many experiments must be run to understand the true root cause and build solutions from scratch. Even if you think you know the answer, verify. Go and see.

How do you see the potential for being “most efficient”?

With the proper processes and Lean tools in place we will be able to exceed financial targets. Our operations will be running efficiently and constantly improving. A key element of that is clarity of how every action impacts the financials of the organization – and their associated cost or benefit. Everyone should understand how their actions affect the bottom line. Consequently, what could be perceived as a small improvement on the shop floor could inflate to a massive impact on the bottom line, allowing for additional CAPEX or improvement opportunities.

When you aren’t in the KAMAX plant, what are your hobbies?

I am a very active outdoorsman. Year-round, I enjoy hiking, fishing, and camping. Recently I have gone on remote fishing excursions in Northern Canada where you have to be flown into the otherwise inaccessible lakes. I also enjoy downhill skiing and travel whenever possible. I have been to almost all the US States – Alaska is my next and final.

Most importantly, I make sure to have a good American beer to relax. However, when I am away from home, I will settle for a chilled German Kölsch.

KXpress